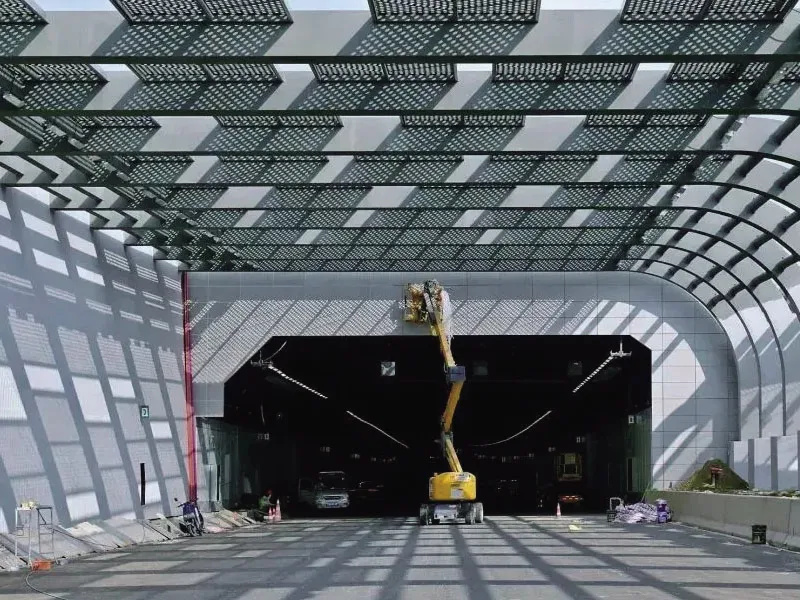

The Wuxi Taihu Tunnel, the longest underwater tunnel in China, features a "two-tunnel-one-service-corridor" structure, with a total length of 10.79 km. It has six lanes in both directions, a clear width of 40.6 meters, a clear height of 7.25 meters, and a 4.5-meter-wide service corridor in the middle.

The tunnel is built on the soft foundation of the Taihu Lake bed and is designed to withstand a seismic intensity of level 7, while also meeting stringent environmental protection requirements for the surrounding ecosystem. To address these challenges, the project employs a combination of grouting sleeves and rolled straight-thread sleeves at critical sections, providing a differentiated solution.

Immersed Tube Segment Joints: For the connection of Φ36mm HRB500 longitudinal main rebars in areas with fluctuating water pressure, grout couplers were used to connect 1,840 main rebars. The connections passed water pressure tests (1.5 times the design value) with no leakage.

Standard Segment Side Walls: Thread bar couplers were used for rapid connection.

Superior Quality Stability: Threads are processed using CNC machines, ensuring high thread precision and excellent seismic performance.

Improved Efficiency: Single-joint construction is faster, delivering significant economic benefits.

Environmental Protection: No welding fumes or rebar waste, reducing CO2 emissions and safeguarding the surrounding ecosystem.