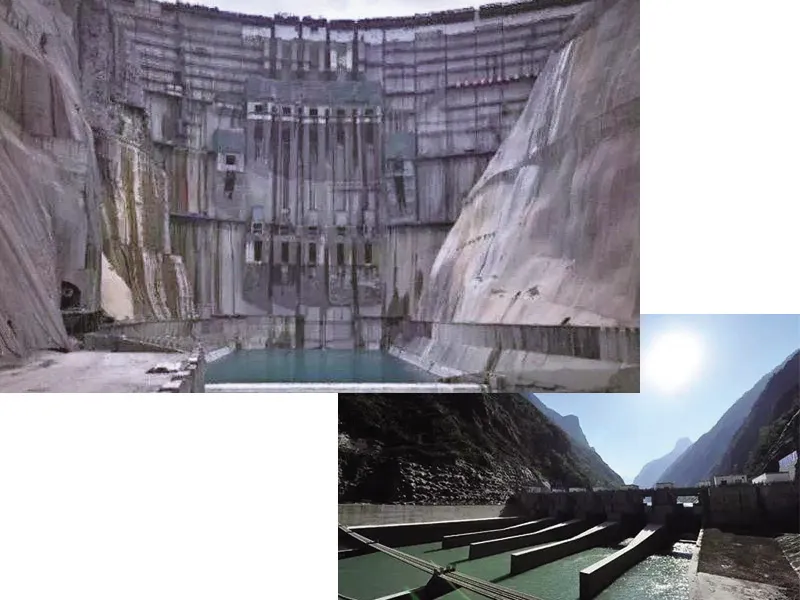

Jinping Hydropower Station is recognized by the hydropower community both domestically and internationally as the most challenging hydropower station in the world in terms of construction management, construction layout, engineering technology, and environmental hazards. Jinping I relies primarily on the high dam to create a head of approximately 300 meters; Jinping II utilizes the Jinping Bend's approximately 300-meter head by straightening the bend. Its total installed capacity is 8.4 million kilowatts.

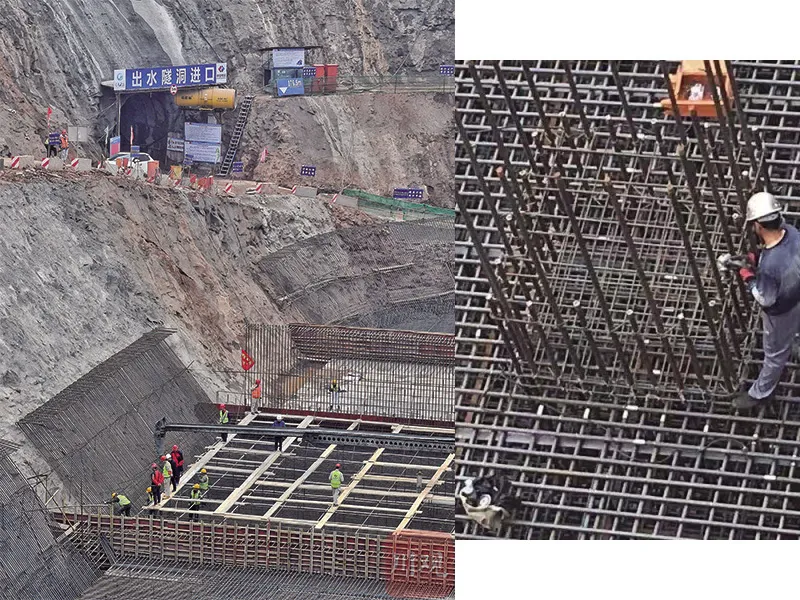

In large hydropower projects like Jinping Hydropower Station, vertical and inclined shaft structures are often subjected to high stresses, complex loads, and harsh environments, placing extremely high demands on the strength, precision, and durability of rebar connections. Straight thread sleeve connection technology, due to its high reliability and ease of construction, has become one of the preferred solutions for connecting rebar in vertical and inclined shafts.

The tensile strength of the joint is ≥ the standard value of the parent steel material, meeting the seismic requirements of hydraulic structures.

Fatigue resistance.

High thread fit precision.

Strong spatial adaptability.