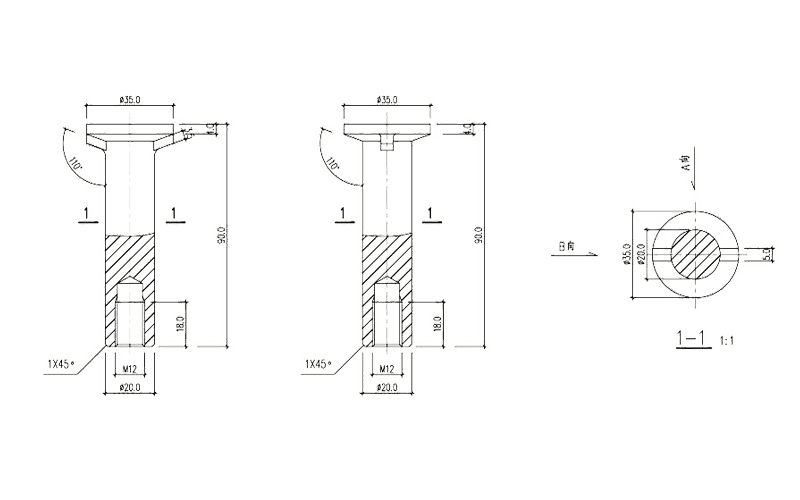

Stainless steel precast coupler is a type of pre-installed component used in building structures, made of stainless steel with excellent corrosion resistance and durability. The rebar coupler is tubular, featuring internal threads to facilitate attachment to external components via bolts.

It is embedded in the structure before concrete is poured, serving as a fixing or connection point for other components, such as pipes, equipment, or steel structures.

Corrosion-resistant, made from 304/316 stainless steel.

Factory-prefabricated embedded sleeves enable standardized production, eliminating on-site drilling and installation.

Enhances construction efficiency, avoids intensive tunnel construction, and enables rapid installation.

Application of Stainless Steel Precast Coupler

Stainless Steel Precast Couplers have been widely used in railway construction projects, effectively solving the problem of fixing pipeline brackets, contact network brackets, and evacuation platform brackets in tunnels, and have become a standard design solution for installation and fastening in tunnels.

The pre-embedded stainless steel sleeve serves as the anchor point for the fine-tuning bolt and is connected to the upper track plate through a screw to achieve ±0.5mm grade elevation adjustment.

The connection nodes between the diaphragm wall and the basement beam and slab adopt the pre-embedded straight thread sleeve process to ensure the accuracy of the reverse working interface.

The corrosion depth of stainless steel sleeves in a simulated salt spray environment over 30 years is less than 0.01mm, which is far superior to that of carbon steel sleeves.