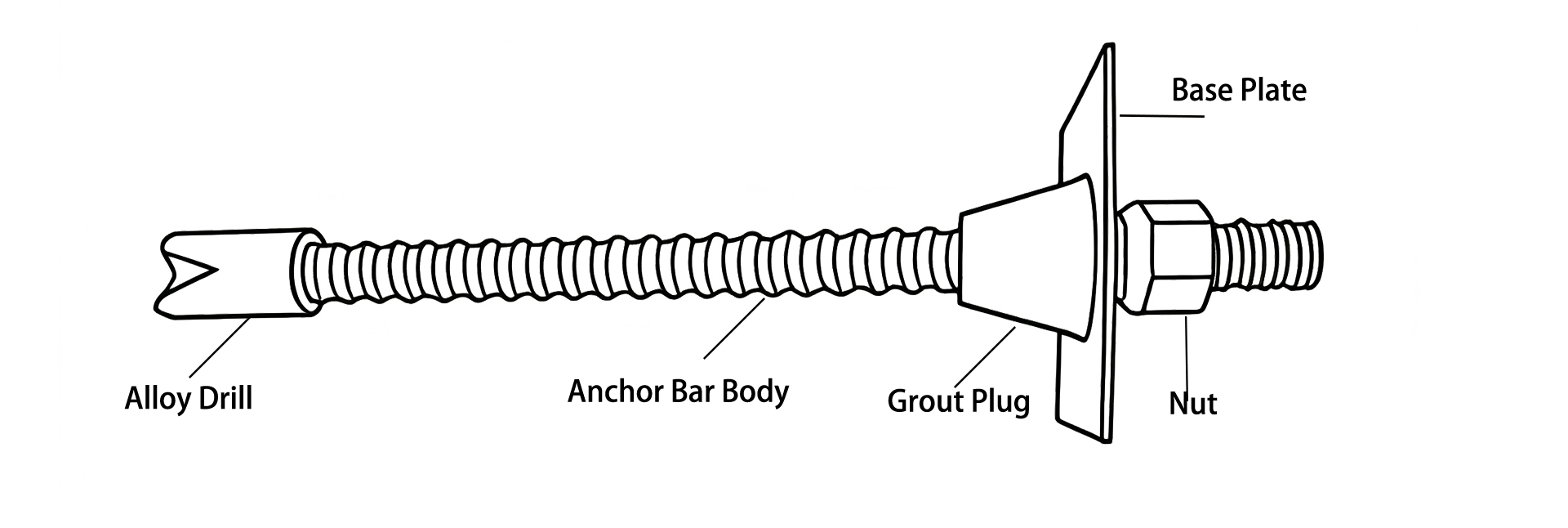

The hollow-type grouting hollow anchor bolt uses 45c/37MnSi hollow steel pipe with standard threads on the surface as the drill pipe, and an alloy drill bit is set at the front end of the drill pipe. The self-drilling hollow grouting anchor bolt series integrates functions such as drilling, grouting and anchoring. Self drilling rock bolts is widely used in rock mass that is fragmented, difficult to form holes and where drilling first and then installing anchor bolts cannot be achieved.

| ||||||

| Diameter | Thickness | Length | Lower Yield Force | Maximum Force | Elongation After Fracture | Total Elongation at Maximum Force |

| 25mm | 4~8mm | 2~6m | ≥150kN | ≥200kN | ≥8% | ≥5% |

| 32mm | ≥280kN | ≥360kN | ||||

| 38mm | 6~12mm | ≥400kN | ≥500kN | |||

| 51mm | ≥630kN | ≥800kN | ||||

The body of self-drilling anchor bolts is preferably composed of hollow high-strength steel pipes with standard threads on the surface, alloy drill bits, stoppers, washers and hexagonal nuts.

Self drilling rock bolts has strong penetrating power, enabling anchor rods to pass through various types of rocks and improve the surrounding rock and soil mass. Self drilling rock bolts is mainly suitable for construction areas with weak surrounding rocks and severe hole collapses in fault and broken zones.

No pre-drilling is required. Self drilling anchor bolt system also serves as the anchor bar. After drilling into the formation and grouting, a fully bonded anchor rod is formed. Drilling, anchoring, grouting and anchoring are all completed in one process at once.

The self-drilling anchor bolt construction process eliminates the step of pulling out the drill pipe, which can effectively control the fullness of the anchor bolt grouting. Longer anchor rods can be installed in narrow Spaces, and the construction efficiency is increased several times.

Support for strata with weak surrounding rock, fault zones, sand and gravel, etc., which are prone to collapse after drilling. In projects such as advanced tunnel support, radial support, and various slope treatments, self drilling rock bolts can effectively improve the surrounding rock and achieve the ideal support effect.

Support for strata that are prone to collapse after drilling, such as weak surrounding rock and fault zones.

Self drilling rock anchor can effectively improve the surrounding rock in various slope treatment projects.

Effectively controlling the fullness of anchor bolt grouting plays a significant role in tunnel support.