Without taking any anti-corrosion measures, the anchor bars in the anchor head section are prone to rust. For temporary anchor rods, although it may not necessarily endanger the bearing capacity, it may affect the subsequent secondary tensioning, anchor bar removal and recovery, and other work. Moreover, due to the poor appearance, it is easy to cause misjudgments about the safety of the anchor rods and even the safety of the engineering structure. Therefore, anti-corrosion hollow anchor rods are proposed.

| Diameter | Thickness | Yield Strength | Tensile Strength | Yield Force | Maximum Force | Elongation After Fracture |

| 25mm | 5mm | 325MPa | 490MPa | ≥102kN | ≥153KN | ≥21% |

| 25mm | 7mm | ≥128kN | ≥193KN | |||

| 28mm | 5.5mm | ≥126kN | ≥190KN | |||

| 32mm | 6mm | ≥159kN | ≥240KN |

Anti-corrosion coating protection, including epoxy-coated steel bars, as well as anti-corrosion coatings applied to the surfaces of metal components such as anchor bars, anchors, anchor pads, metal carriers and end caps.

The epoxy coating is sprayed in the factory environment. After curing, the thickness of the coating is greater than 220um, and when it is grade two, it is greater than 180um. The length of the epoxy coating extending into the anchor seat is greater than 50mm.

Permanent anchor rods in corrosive environments should adopt an engineering grade anti-corrosion protection structure design. Permanent anchor rods in non-corrosive environments and temporary anchor rods in corrosive environments also need to adopt an anti-corrosion protection structure design.

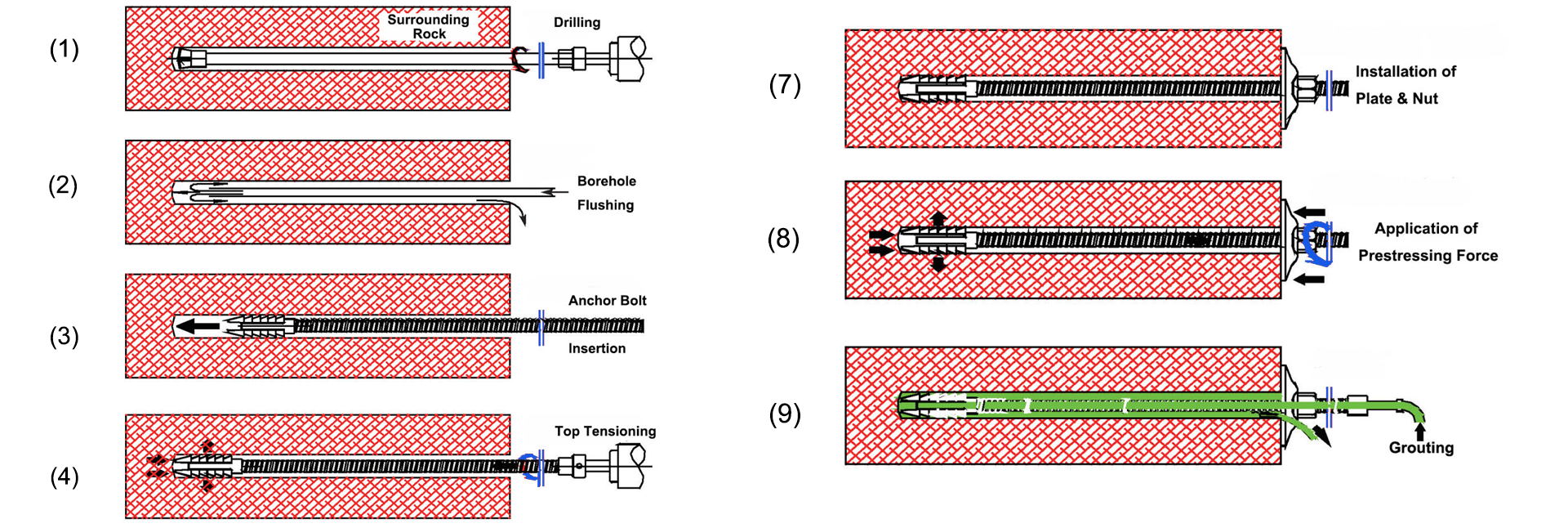

The anti-corrosion anchor bolt has a simple structure and is convenient for construction.

Anti-corrosion anchor rods have strong durability and are mainly used in railway systems for arch support and local support.

Anti-corrosion anchor rods can be used for slope support, foundation pit support and pile foundation support.