Headed Bar, also widely known as threaded rebar anchor plates, represent an innovative and highly efficient method of mechanical anchorage in modern concrete structures. This technology offers significant benefits compared to traditional rebar anchorage techniques. Specifically, the adoption of this mechanical rebar anchorage system within complex joints dramatically simplifies rebar detailing and installation on-site. By replacing the cumbersome hooked bars, it effectively mitigates rebar congestion and the associated difficulties in tying densely packed steel. Furthermore, the use of anchor plates inherently enhances the structural performance of the connection node and, critically, improves the quality of concrete pouring and consolidation, ensuring better long-term durability and structural integrity.

| Specifications | Size (Diameter*Thickness) | Pitch | Weight(KG) |

| 12 | 33*15.5 | 2 | 0.08 |

| 14 | 33*15.5 | 2.5 | 0.08 |

| 16 | 38*16 | 2.5 | 0.08 |

| 18 | 43*18 | 2.5 | 0.13 |

| 20 | 49*20 | 2.5 | 0.15 |

| 22 | 52*22 | 2.5 | 0.2 |

| 25 | 60.5*25.5 | 3 | 0.3 |

| 28 | 66*29 | 3 | 0.38 |

| 32 | 76.5*32 | 3 | 0.58 |

| 36 | 85*36 | 3 | 1 |

| 40 | 95*40 | 3 | 1.3 |

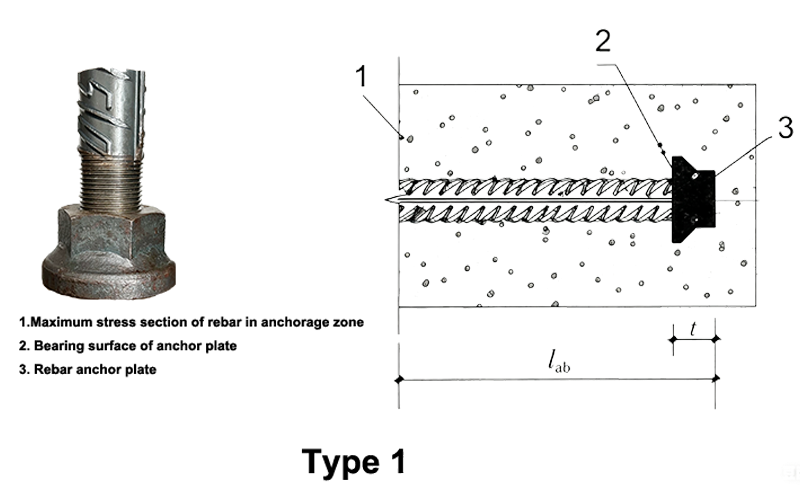

Type 1:

Hexagonal headed bar: An anchor plate that combines the pad (pressure-bearing plate) and the nut (connection end) into one and is connected to the top of the reinforcing bar by a straight thread.

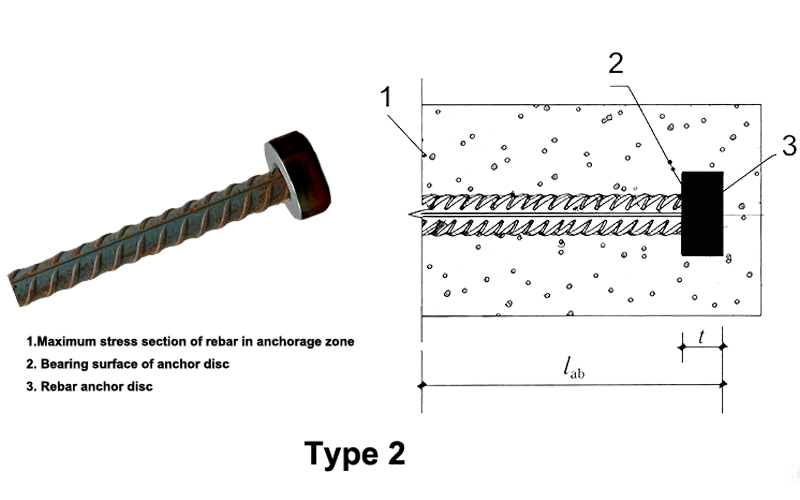

Type 2:

Circular headed coupler (Terminator): This system involves connecting the circular headed coupler (or terminator coupler) to the straight threaded end of the rebar.

Compared with the traditional steel bar anchoring technology, the application of mechanical steel bar anchoring technology at complex nodes can simplify the construction of steel bar engineering, reduce the difficulty of binding dense and congested steel bars, improve the load-bearing performance of nodes, and enhance the quality of concrete pouring, demonstrating how specialized reinforcement coupler types evolve to solve specific anchorage challenges.

Headed bars can be produced in factories and supplied commercially, replacing the traditional bending steel bar anchoring and straight steel bar anchoring, which can save steel and facilitate construction. For example:

The headed bar reinforcement is used to replace the traditional bent reinforcement for the beam-column joints of the frame structure.

It is used as a shear reinforcement for simply supported beam supports, beams or slabs, replacing the anchoring of traditional bent and straight bars.

Headed bars have a wide range of applications. Civil engineering and construction projects, including buildings, bridges, water conservancy and hydropower, nuclear power plants, subways, etc., all require a large amount of steel bars and need steel bar anchoring technology.

The anchoring operation time for a single reinforcing bar is no more than 3 minutes (saving 50% of the working hours compared to hook binding), and it can be prefabricated for construction (such as completing the installation of the anchoring plate before the overall hoisting of the anchor reinforcing bar cage).

Mechanical anchoring has no heat-affected zone for welding. In areas frequently hit by typhoons, the anchor plate nodes have no slip deformation after 2 million cycle load tests, which is superior to welded anchoring.

Instead of the traditional hook anchoring, the cross-interference in the densely reinforced steel area is reduced. The transverse connecting bars use anchor plates instead of hooks to solve the problem of steel bar collision in the cast-in-place section.