The common grouted rock bolt is a type of anchor bolt with a full threaded steel pipe as the rod body, and anchoring materials are filled in the anchor holes and inside the anchor pipe.Grouted rock anchors belongs to passive reinforcement, allowing the reinforced structure to have appropriate deformation. Gouted rock anchors has been successfully applied in geotechnical anchoring projects such as tunnel construction, slope treatment, foundation pit wall protection, and mining, achieving good economic benefits.

| |||||||

| Specification | Diameter | Thickness | Yield Strength | Tensile Strength | Yield Force | Maximum Force | Elongation After Fracture |

| 25×5 | 25mm | 5mm | 325MPa | 490MPa | ≥102kN | ≥153KN | ≥21% |

| 25×7 | 25mm | 7mm | ≥128kN | ≥193KN | |||

| 28×5.5 | 28mm | 5.5mm | ≥126kN | ≥190KN | |||

| 32×6 | 32mm | 6mm | ≥159kN | ≥240KN | |||

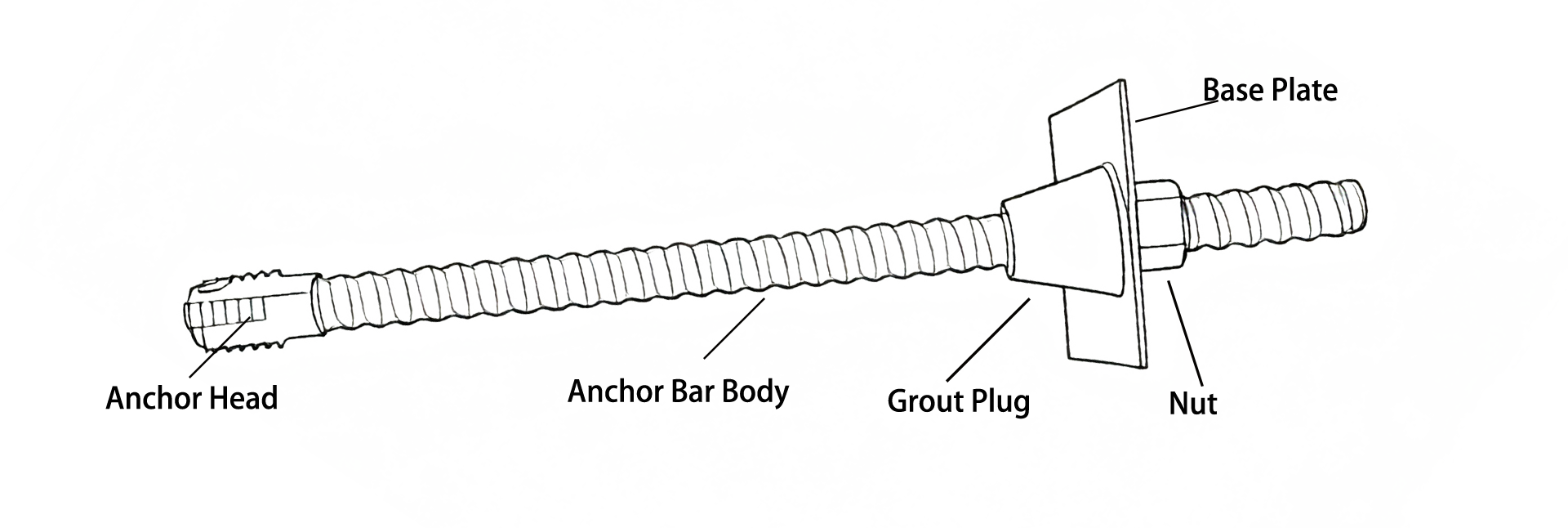

The body of a common hollow grouting anchor bolt is composed of a hollow high-strength steel pipe with standard threads on grouted rock anchors surface, a grouting plug, a backing plate and a hexagonal nut.

The anchor bolt body is rolled from 45c and 37MnSi steel pipes. Compared with reinforced steel anchor bolts, hollow anchor bolts have stronger shear and bending resistance under the same strength. The rod body is hollow structure and can be used as a grouting pipe or exhaust pipe, avoiding the loss of mortar caused by the pulling out of traditional grouting pipes.

Grouted rock bolt adopts continuous threads that match the nut, with a pitch of 8mm to 13mm and a thread height of 1.5mm to 2mm. The installation speed of the nut is faster, and grouted rock anchors can avoid the problem of inability to tighten caused by thread collision. Grouted rock anchors is also convenient to install washers and nuts.

The common hollow anchor bolt is equipped with a stopper and a plastic anchor head, which is processed from pollution-free and corrosion-resistant plastic. Grouted bolt can make the bolt body more neutral in the borehole, thereby enhancing its anti-corrosion ability and the anchoring force of the anchor bolt.

Grouting hollow anchor rods belong to passive support anchor rods. Pressure grouting of anchor rods through hollow rod bodies can quickly form supporting forces and control the stability of surrounding rocks.

It can be used in rock mass reinforcement projects where the requirements for displacement control after stratum excavation are not strict.

It is used for support in underground projects and can be used to install longer anchor rods in narrow Spaces.

The grouting is full and can achieve pressure grouting, which improves the quality of the project.