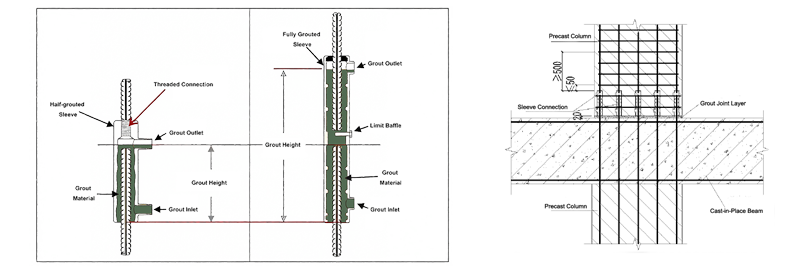

Grout couplers, also known as grouting sleeves or grout splice coupler, are high-performance mechanical connectors essential for rebar butt splicing in modern construction. Each coupler is precisely designed with a grout inlet port and a vent port to ensure a complete and solid connection.

Grout coupler range includes both semi-grouted sleeves and fully-grouted sleeves, offering flexible solutions for various concrete structural applications.

The principle of operation relies on a specialized grout mixture which, upon hardening, integrates the rebar ends and the sleeve, achieving seamless load transfer and forming a structural continuum. Independent tensile tests have consistently shown that CHEERON grout couplers provide a connection strength higher than the parent material strength of the rebar itself. This exceptional performance makes this coupler joint in reinforcement ideal for projects demanding superior seismic resistance and maximum structural integrity.

| Semi-grouting | |||||

| Rebar Dia(mm) | Standard Sizes(mm) | ||||

| L | D | L1 | D1 | D2 | |

| 12 | 140 | 112 | 24 | 13 | 36 |

| 14 | 157 | 125 | 24 | 14.7 | 38 |

| 16 | 174 | 150 | 30 | 16.5 | 40 |

| 18 | 193 | 160 | 31 | 19 | 42 |

| 20 | 206 | 168 | 33.5 | 21 | 44 |

| 22 | 231 | 185 | 39 | 23 | 48 |

| 25 | 259 | 212 | 43 | 26 | 53 |

| 28 | 288 | 238 | 48 | 29 | 61 |

| Full-grouting | |||||||

| Rebar Dia(mm) | Standard sizes(mm) | ||||||

| L | L1 | L2 | L3 | D | D1 | D2 | |

| 12 | 250 | 120 | 108.5 | 21.5 | 44 | 25 | 16 |

| 14 | 280 | 135 | 123.5 | 21.5 | 46 | 25 | 16 |

| 16 | 310 | 150 | 138.5 | 21.5 | 48 | 25 | 16 |

| 18 | 350 | 170 | 158.5 | 21.5 | 50 | 25 | 16 |

| 20 | 370 | 180 | 168.5 | 21.5 | 52 | 25 | 16 |

| 22 | 410 | 200 | 188.58 | 21.5 | 54 | 25 | 16 |

| 25 | 450 | 220 | 208.5 | 21.5 | 58 | 25 | 16 |

| 28 | 505 | 250 | 233.5 | 21.5 | 62 | 25 | 16 |

| 32 | 570 | 280 | 268.5 | 21.5 | 66 | 25 | 16 |

| 32 | 650 | 320 | 308.5 | 21.5 | 75 | 25 | 16 |

| 36 | 650 | 320 | 308.5 | 21.5 | 75 | 25 | 16 |

| 40 | 810 | 405 | 362.5 | 21.5 | 95 | 17.5 | 17.5 |

TYPE 1: Semi-grouting type

One end is connected by sleeve grouting, and the other end is connected to the grouting sleeve of the reinforcing bar by mechanical connection.

TYPE 2: Fully grouting type

A grouting sleeve with both ends connected by sleeve grouting.

Semi-grouting sleeve (joint): In the component factory, grout coupler is necessary to process the steel bar threads

Fully grouting sleeve (joint): No need to process the steel bar threads in the component factory, making construction more convenient.

Grout coupler is applicable for splicing HRB and TMT rebars with diameters ranging from 12 mm to 40 mm in prefabricated composite concrete structures.

The applications specifically include the connections for:

Longitudinal load-bearing reinforcement in precast columns and precast beams (Precast Frame Columns and Beams).

Vertical reinforcement in precast shear walls (Precast Shear Walls).

Grouted splice coupler can also be utilized for splicing vertical and horizontal rebar in Cast-in-Place (CIP) structures during the refurbishment or reconstruction of existing buildings (Existing Structure Retrofitting).

For the splicing of load-bearing rebar in vertical precast elements, either semi-grouted sleeves or fully-grouted sleeves may be utilized.

For the connection of longitudinal load-bearing reinforcement in horizontal precast elements at the Cast-in-Place (CIP) closure strip, fully-grouted sleeves can be employed.

Outstanding seismic performance, through the dual effects of chemical bonding and mechanical interlocking between the grouting material and the steel bars, achieves an energy dissipation capacity 1.5 times that of traditional welded joints.

Grout coupler service life reaches 100 years, which is three times that of ordinary welded joints, ensuring long-term durability.

Through the standardized production of prefabricated components and precise on-site assembly, construction becomes more convenient.