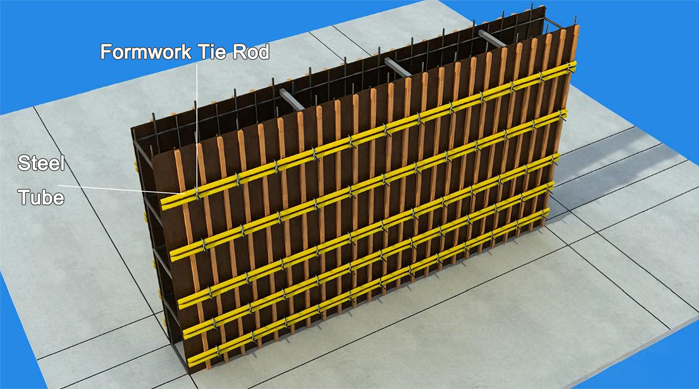

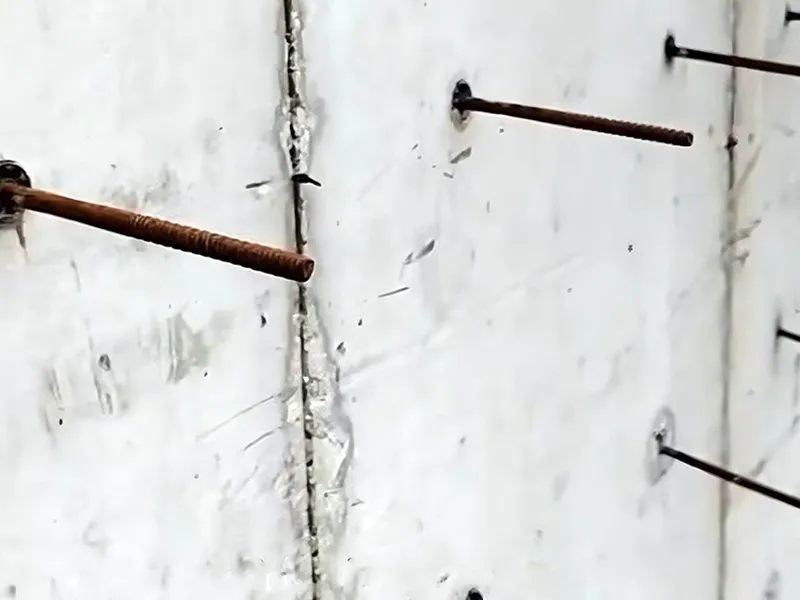

Formwork/Shuttering Tie Rods are industrial materials used in the construction industry for concrete walls. They serve to secure the formwork, control wall thickness, and prevent water leakage.

| Diameter (mm) | Design Value of Axial Tension (KN) | Length/Pitch |

| M12 | 12.9 | Customizable |

| M14 | 17.8 | |

| M16 | 24.5 | |

| M18 | 29.6 | |

| M20 | 38.2 |

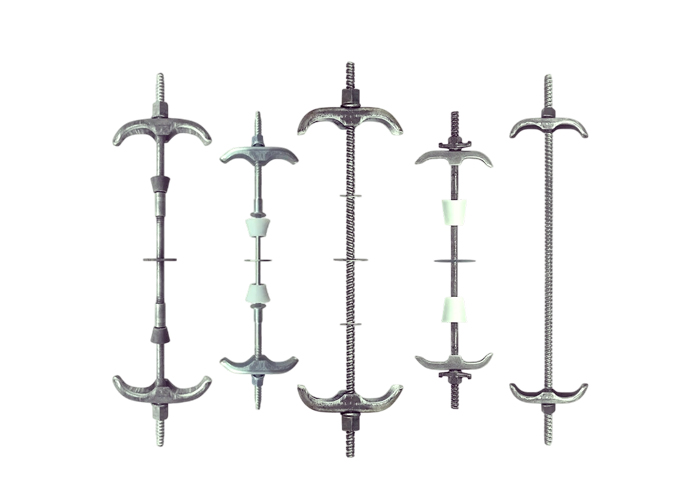

1. Types of Formwork Tie Rods

Ordinary Shuttering Tie Rods consist of a threaded rod, fixing clips, and nuts, without a water-stop plate.

Water-stop Shuttering Tie Rods are made up of a threaded rod, a water-stop plate, and fixing clips. The water-stop plate is welded in the middle section of the rod, with fixing clips and nuts placed at both ends for securing.

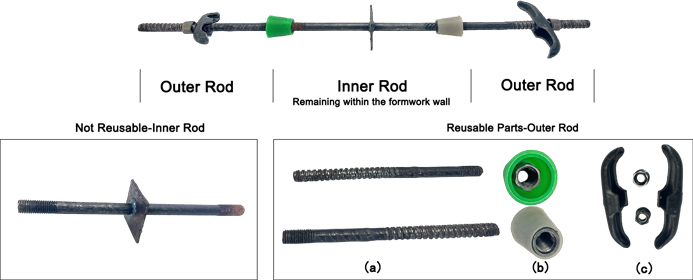

Three-piece Water-stop Shuttering Tie Rods consist of an inner threaded rod connected to two symmetrical outer threaded rods. The inner threaded rod comes with a water-stop plate, the end rods are equipped with fixing clips and tightening nuts, and the connection between the inner and outer rods is fitted with a coupling sleeve.

2. Advantages of Formwork Tie Rods

They have high material strength, made of high-quality steel with a tensile strength ≥ 400MPa; feature a waterproof design, with the middle water-stop plate preventing lateral water penetration; the outer rod of a three-piece water-stop tie rod can be reused, reducing costs and making construction more convenient.

3. Functions of Formwork Tie Rods

Used for supporting the formwork of concrete components such as walls, columns, and beams. They pass through the formwork and, with fastening at both ends, tie the formwork on both sides into a single unit to resist lateral pressure during concrete pouring, preventing formwork blowouts and deformation.