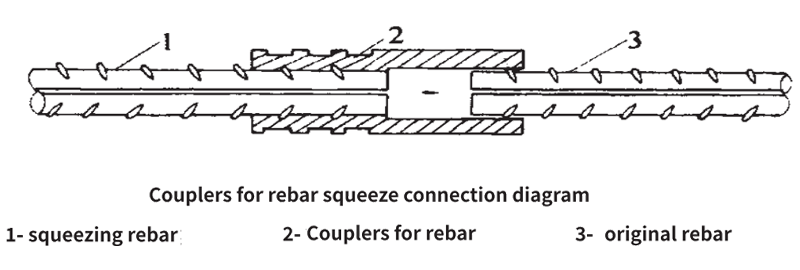

A type of rebar coupler without internal threads. When connecting, the crimping rebar coupler is placed over both ends of the joint of two reinforcing bars and placed in a dedicated pressure device. According to the specified number of pressing passes and indentations, the coupler undergoes plastic deformation through pressure, thereby connecting the two reinforcing bars together.

| ||||

| MODEL | L(mm) | OUT DIA(mm) | THK(mm) | W(kg) |

| φ16 | 100 | 30 | 4.5 | 0.28 |

| φ18 | 118 | 34 | 5.7 | 0.47 |

| φ20 | 120 | 36 | 6 | 0.53 |

| φ22 | 132 | 40 | 6.8 | 0.74 |

| φ25 | 150 | 45 | 7.5 | 1.04 |

| φ28 | 168 | 50 | 8 | 1.45 |

| φ32 | 192 | 55 | 9 | 2 |

| φ36 | 216 | 63 | 10 | 2.83 |

| φ40 | 240 | 70 | 11 | 3.84 |

Improving work efficiency: Cold extrusion sleeves have low requirements for construction conditions, such as when the steel bars are fixed and cannot be rotated, or when connecting steel bar cages, etc.

The connection joint has high strength: The extruded connection sleeve is made of high-quality 45c/40cr carbon steel, which has excellent seismic performance.

Strong applicability: Suitable for various weather conditions and different steel bar diameters (16-40mm), with stable performance.

Safety and environmental protection: It does not produce sparks or toxic and harmful gases, avoids air pollution, and minimizes the possibility of fire to the greatest extent.

Crimping rebar coupler types are more suitable for specific projects that require high seismic resistance and precise alignment (such as nuclear power plants, hospitals), large-diameter steel bars (≥25mm), or parts subjected to dynamic loads.

It is applicable to environments with high fire protection requirements for tunnels, such as the circumferential main reinforcement connection in tunnel reinforced concrete linings.

Mechanical cold extrusion joints are used between the main ribs and the connecting ribs of the pier cap. Before use, the joint sleeves are coated with epoxy resin as per regulations. After the extrusion connection is completed, the damaged parts on the surface of the sleeves also need to be repaired.

The cold extrusion construction process of the secondary lining steel sleeve for tunnels significantly reduces the electricity consumption on the construction site, greatly saves human resources, and compared with lap welding, it greatly saves steel.

The CHEERON cold extruded sleeve connection can achieve or even exceed the strength of the steel bar base material, fully meeting the seismic design requirements of nuclear power plant structures.