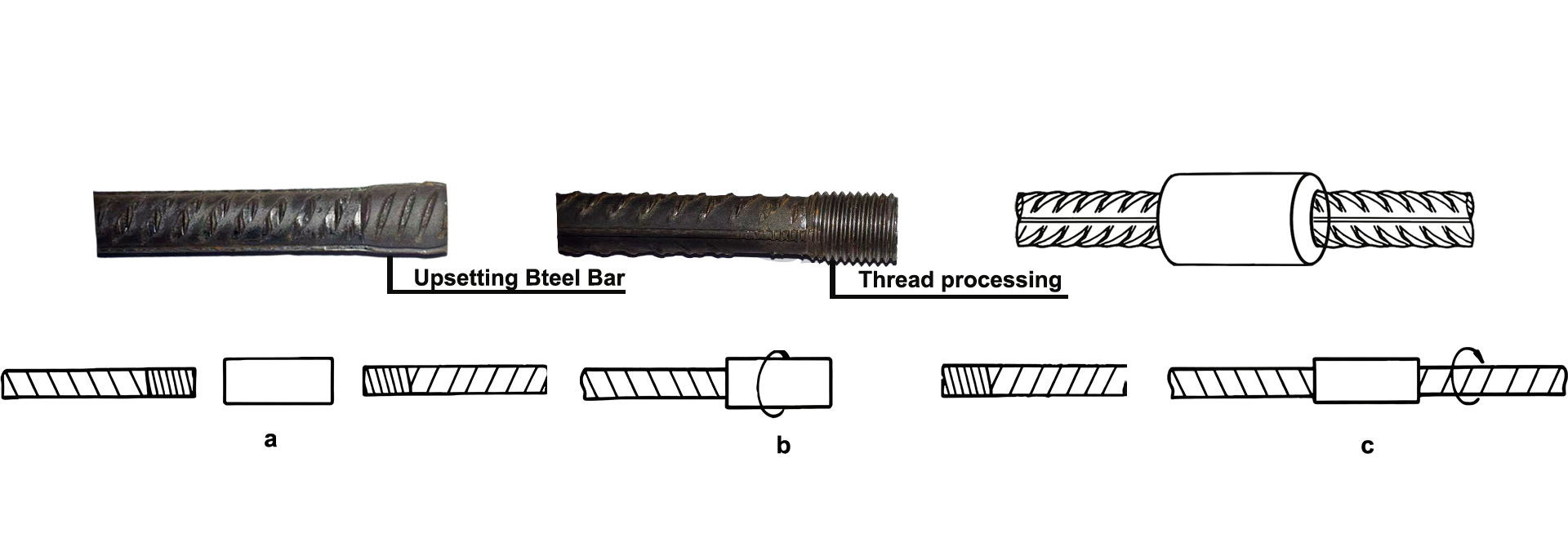

Unlike the common straight thread connection, the upsetting straight thread sleeve connection uses a upsetting machine to first upsetting the end of the reinforcing bar, and then uses a dedicated threading machine to thread the upsetting section of the reinforcing bar to form the connection thread. This technology, through the dual strengthening of "upsetting and toughening + precision threads", has become the core solution for steel bar connections in bridges, high-rise buildings, hydropower stations, etc.

| Specifications | Outside Diameter (mm) | Inside Diameter (mm) | Length (mm) | Thread Size (mm) |

| 12 | 22 | 11.9 | 30 | M14*2 |

| 14 | 24 | 13.9 | 34 | M16*2 |

| 16 | 26 | 17.4 | 40 | M20*2.5 |

| 18 | 29 | 19.4 | 44 | M22*2.5 |

| 20 | 32 | 20.9 | 48 | M24*3 |

| 22 | 36 | 23.9 | 52 | M27*3 |

| 25 | 40 | 26.3 | 60 | M30*3.5 |

| 28 | 44 | 29.3 | 66 | M32*3.5 |

| 32 | 50 | 31.8 | 72 | M36*4 |

| 36 | 56 | 34.8 | 80 | M39*4 |

| 40 | 62 | 40.3 | 90 | M45*4 |

The connection strength is high. The upsetting process increases the cross-section of the steel bar joint area. In tensile tests, it all breaks off from the base material, and its strength is higher than that of the steel bar base material. It is particularly suitable for heavy-load parts such as the main span of large Bridges.

The engagement between the upset section and the sleeve is tighter, and there is no slippage under repeated loads (such as typhoons and earthquakes), which is superior to the common straight thread connection.

The construction efficiency is relatively high, but it requires specialized equipment (such as steel bar upsetting machines and thread rolling machines).

Threaded sleeve connections can be used on site to connect 12 to 50mm(#4 to #14) vertical, horizontal or any inclination Angle HRB, TMT and other high-strength rebar with threaded end.

Construction method: The connection of the pier thickening sleeve is to first use a pier thickening machine to roughly process one end of the reinforcing bar, and then use a threading machine to thread the pier thickening section. Through the specially designed straight thread pier thickening sleeve at the end of the reinforcing bar, an integral reinforcing bar connection is formed. The installation steps are as follows:

Application: It is suitable for projects such as Bridges and high-speed railways that have high requirements for the connection of steel cages.

The upsetting straight thread connection technology is widely applied to the extension of reinforcing bars in key load-bearing parts such as main beams, piers, and pile foundations (such as HRB500 high-strength reinforcing bars with diameters ranging from Φ28mm to Φ40mm).

It is mainly used for mechanical splicing of steel bars in public venues to ensure structural continuity, accelerate construction and support sustainable disassembly. It is suitable for high-load areas such as roof supports, column and beam interfaces and underground foundations, especially in modular venues.

In hydropower station projects, the difficulties in steel bar connection mainly stem from the complexity of the engineering environment and the high standards of structural requirements. The upsetting sleeve connection has high strength and can withstand extreme conditions such as water pressure, earthquakes and long-term immersion.