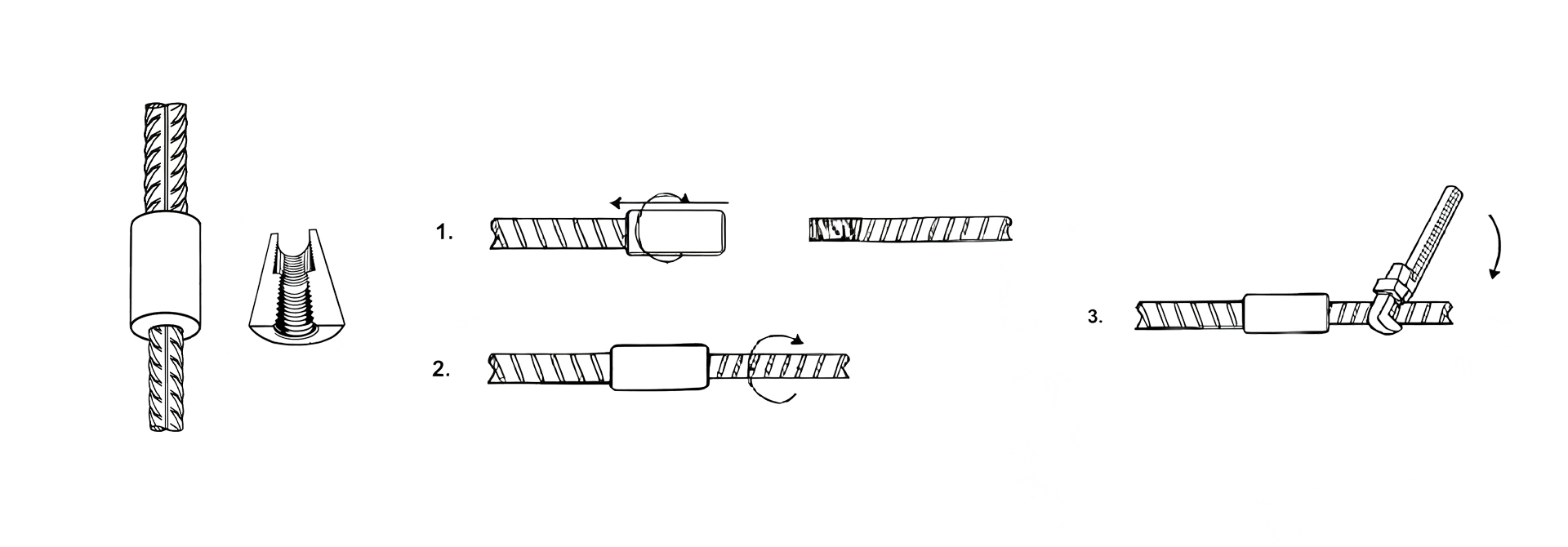

The variable diameter steel bar straight thread connection system is to connect steel bars of different diameters. Simply put, one end is the thread for connecting thick steel bars, and the other end is the thread for connecting thin steel bars.

| ||||

| Rebar Diameter | Outer Diameter(mm) | Length(mm) | ||

| mm | ||||

| Rebar Strength Level ≤400 | Rebar Strength Level 500 | Rebar Strength Level ≤400 | Rebar Strength Level 500 | |

| 12 | 18 | 19 | 28 | 32 |

| 14 | 21 | 22.5 | 32 | 36 |

| 16 | 24 | 25.5 | 36 | 40 |

| 18 | 27 | 28.5 | 41 | 46 |

| 20 | 30 | 31.5 | 45 | 50 |

| 22 | 32.5 | 34.5 | 49 | 54 |

| 25 | 37 | 39.5 | 56 | 62 |

| 28 | 41.5 | 44 | 62 | 68 |

| 32 | 47.5 | 50.5 | 70 | 76 |

| 36 | 53 | 56.5 | 78 | 84 |

| 40 | 59 | 62.5 | 86 | 92 |

| 50 | 74 | 78 | 106 | 112 |

It eliminates the need for inserting or planting threaded rebar, facilitating construction.

Ensure that the force is transmitted in a straight line.

High tensile strength, meeting ISO international standards

The construction operation is convenient and can be carried out in all directions and around the clock.

Customizable, it accelerates the project progress.

Application: It is mainly used in cases where the diameters of the reinforcing bars at both ends are different. For instance, in building columns, the bars are generally thinner as they move upwards. This is where variable diameter bar straight thread sleeves are used.

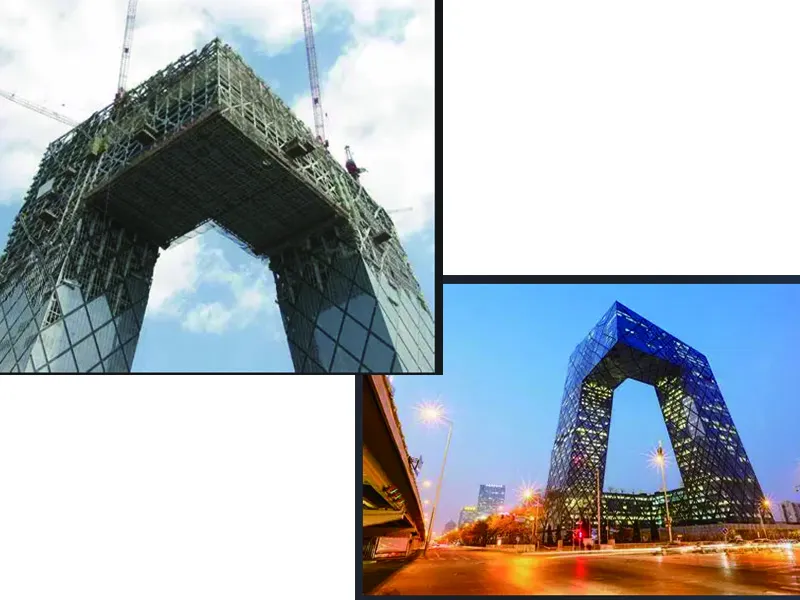

In the construction of steel bar connection in super high-rise buildings, the straight thread sleeve connection technology has become the preferred method for steel bar connection of core load-bearing components (such as giant columns, core tube shear walls) due to its high efficiency and reliability.

The variable diameter steel bar straight thread sleeve, through refined seismic performance design, effectively responds to various seismic loads.

The connection of the reducer sleeve ensures that the cantilever node can withstand the action of external forces such as wind load and seismic load.