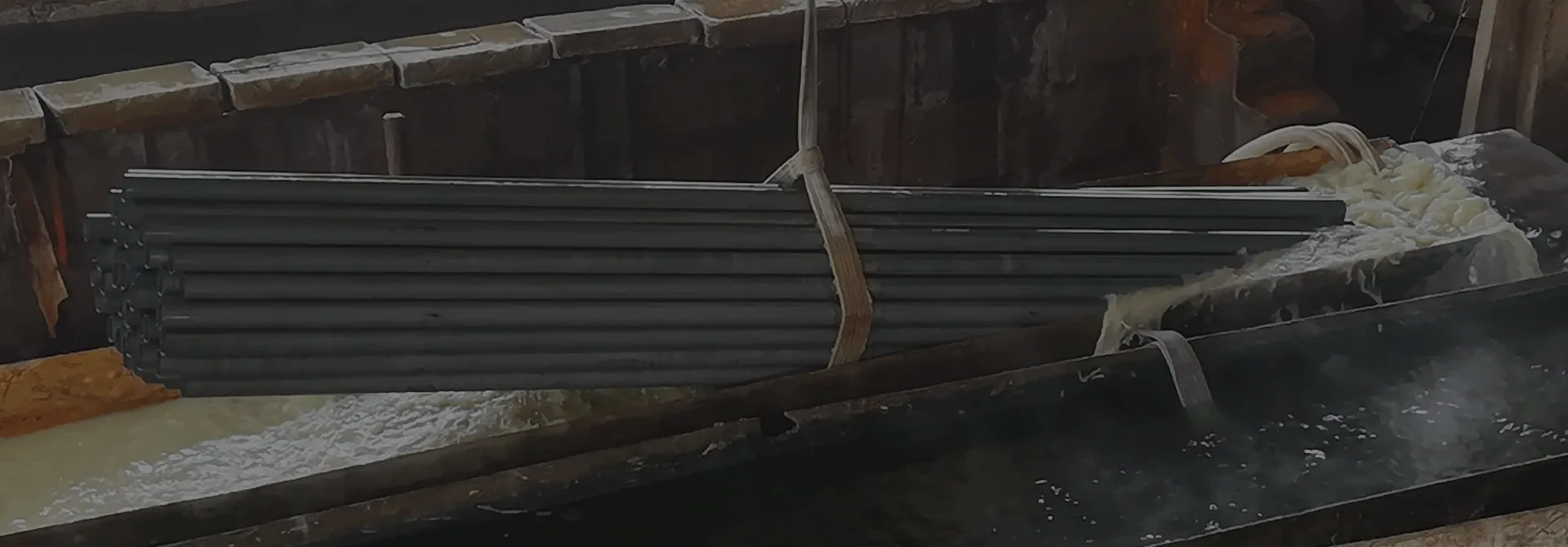

Seamless steel pipe is a kind of long steel with a hollow cross-section and no seams around the periphery, which is different from welded steel pipe. Seamless steel pipes are classified according to material, application, specification, etc. Classified by material, there are carbon steel material, stainless steel material, alloy material, etc. The specifications of seamless steel pipes are indicated by their external dimensions - outer diameter, length, and wall thickness. Specifically, for instance, structural stainless steel seamless pipes are widely used as corrosion-resistant pipes, structural components and parts in industry. The boiler and superheater are made of seamless carbon steel pipes.

Seamless, one-piece, uniform, better mechanical properties.

Strongest pressure, high safety.

Better corrosion resistance, longer life.

Wider use, harsh condition applicable.

Higher, more complex production requirements relatively.

CHEERON adopts advanced cold rolling technology, is equipped with high-precision molds and CNC equipment, and ensures the precise production of small-diameter thick-walled pipes within the range of 10-100mm.

Each material has undergone strict chemical composition optimization and treatment to ensure that the mechanical properties of seamless steel pipes are in the best condition.

It is applied in multiple fields and provides customized solutions in many areas such as automotive manufacturing, mechanical structures, energy and aviation, petrochemicals, etc.

Seamless steel pipes for structural purposes, seamless steel pipes for fluid transportation, seamless steel pipes for low and medium pressure boilers, seamless steel pipes for high pressure boilers, high-pressure seamless steel pipes for fertilizer equipment, seamless steel pipes for oil cracking, seamless steel pipes for geological drilling, oil drilling pipes, seamless carbon steel pipes for ships, seamless steel pipes for half shaft sleeves of automobiles, high-pressure oil pipes for diesel engines Precision inner diameter seamless steel tubes for hydraulic and pneumatic cylinder barrels, etc.

The specifications of cold-rolled (drawn) seamless steel pipes are indicated by their external dimensions (such as outer diameter or side length) and wall thickness. cheeron can customize small-diameter seamless steel pipes with diameters ranging from 10 to 100mm.

The production process of seamless steel pipes usually consists of hot deformation treatment and cold treatment. Hot deformation treatment is the continuous processing of steel billets under high-temperature conditions to form rough tubes. The equipment used includes punching machines, continuous casting machines and tension reducing machines. The cold treatment process, also known as the finishing process, refers to the process of transforming rough pipes into finished steel pipes under normal conditions. The technological process includes cooling, straightening, cutting, etc.