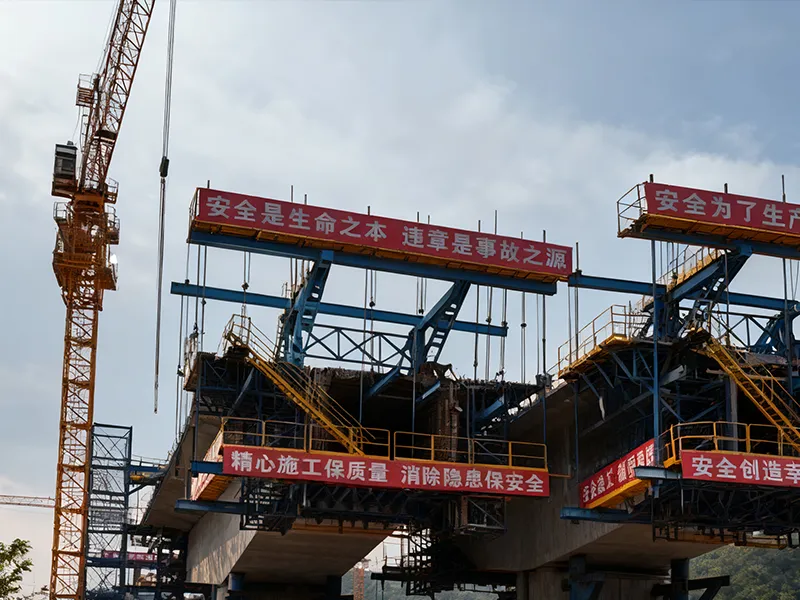

The body of the rock anchor bolt is composed of hollow high-strength steel pipes with standard threads on the surface, grouting plugs, spacers and hexagonal nuts, and is mainly used in rock and soil reinforcement projects. According to the usage scenarios, it can be classified into self-drilling type, ordinary grouting type, expansion shell type, anti-corrosion type, combined type, etc. Hollow anchor rods have been successfully applied in geotechnical anchoring projects such as tunnel construction, slope treatment, and mining, achieving good economic benefits.

Anchor rock to secure underground projects safely.

Widely used in geotechnical reinforcement projects.

Selectable types, fast installation, strong adaptability.

Lower cost, higher efficiency than traditional supports.

Anticorrosive materials/coatings extend service life.

It is rolled from 45c/37MnSi steel pipes, featuring high strength and stable performance.

Produced in cutting-edge facilities, each pipe is tested and its performance exceeds industry benchmarks.

It can be customized according to your project requirements to promote construction efficiency.

Geotechnical rock anchor bolts are used in geotechnical engineering, providing structural support and stability in applications such as tunnel construction, slope reinforcement, and foundation anchoring. Its hollow structure facilitates grouting operations, thereby enhancing the bonding strength and load-bearing capacity.

The anchor bolt body is made by rolling 45c and 37MnSi steel pipes, with a diameter of 25mm to 52mm. The length of the anchor bolt is generally 3.0m to 12m. The grouting plug and anchor head are made of pollution-free and corrosion-resistant plastic, and the grouting plug meets the usage requirement of a grouting pressure of no less than 1MPa. Anchor rods can be treated with anti-corrosion coatings to withstand various environmental conditions.

Installation requires drilling to the specified depth and Angle (self-drilling anchor bolts do not need pre-drilling), and it is necessary to keep the grouting channels in the hollow structure unobstructed. Precise alignment and a firm connection with the surrounding structures are of vital importance. Grouting must be carried out evenly to ensure the best bonding effect. The installation process must strictly adhere to the design standards to ensure the stability and safety of the structure.