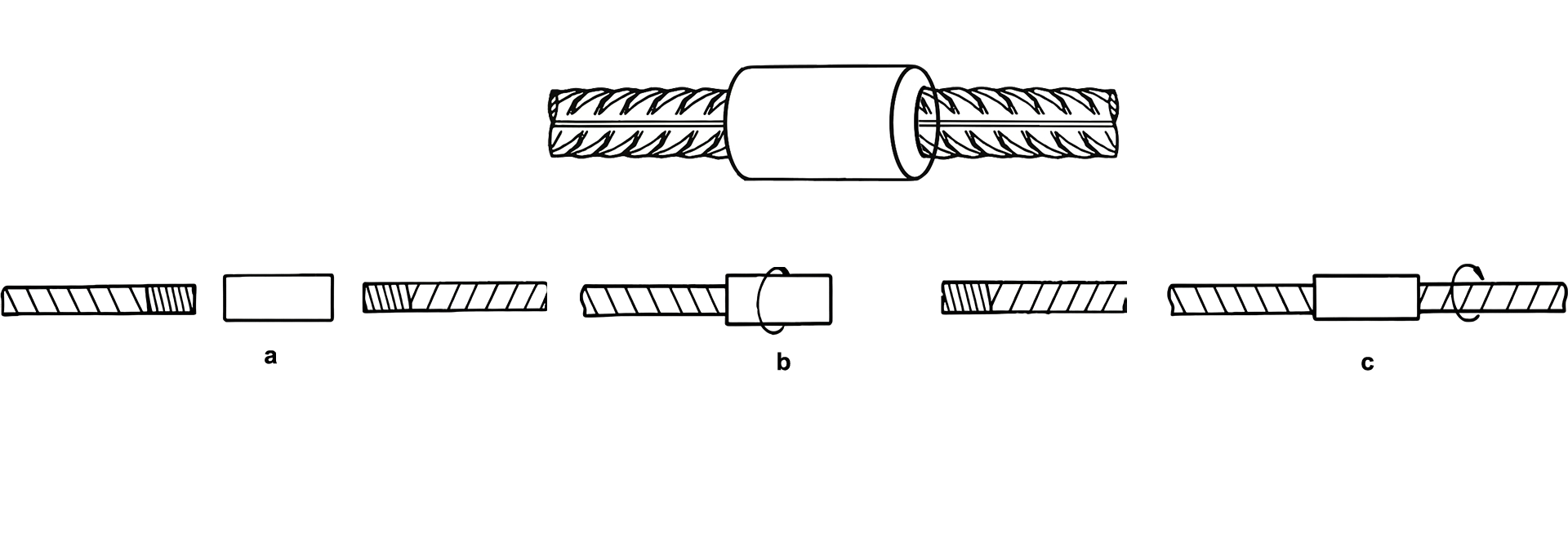

The mechanical connection system for reinforcing bars is the third-generation technology for reinforcing bar joints following binding and welding. The rolling straight thread connection system is one type of mechanical connection for reinforcing bars. The rib stripping and rolling straight thread connection sleeve integrates rib stripping and rolling. It features high precision of formed threads and a long service life of the rolling wheel. It is currently the mainstream technology for straight thread sleeve connections.

| Rebar Diameter mm | Outer Diameter(mm) | Length(mm) | ||

| Rebar Strength Level ≤400 | Rebar Strength Level 500 | Rebar Strength Level ≤400 | Rebar Strength Level 500 | |

| 12 | 18 | 19 | 28 | 32 |

| 14 | 21 | 22.5 | 32 | 36 |

| 16 | 24 | 25.5 | 36 | 40 |

| 18 | 27 | 28.5 | 41 | 46 |

| 20 | 30 | 31.5 | 45 | 50 |

| 22 | 32.5 | 34.5 | 49 | 54 |

| 25 | 37 | 39.5 | 56 | 62 |

| 28 | 41.5 | 44 | 62 | 68 |

| 32 | 47.5 | 50.5 | 70 | 76 |

| 36 | 53 | 56.5 | 78 | 84 |

| 40 | 59 | 62.5 | 86 | 92 |

| 50 | 74 | 78 | 106 | 112 |

Threaded sleeve connections can be used on site to connect 12 to 50mm(#4 to #14) vertical, horizontal or any inclination Angle threaded rebar of HRB, TMT and other high-strength grades.

The connection strength is high, and the tensile strength of the joint is equivalent to that of the base material. The mechanical properties meet the seismic requirements of building structures.

Made of high-quality 45c/40cr steel, the CNC equipment features high thread fit accuracy, reducing quality risks.

It is not affected by high-altitude low-temperature and humid environments, has no heat-affected zone defects, and improves construction efficiency.

Application: Straight thread connections are suitable for large-scale applications due to their high efficiency and cost-effectiveness. It is applicable to the load-bearing parts such as beams, columns and walls of high-rise buildings, Bridges and large infrastructure for earthquake resistance.

Construction method: The rib stripping process is carried out by using a rib stripping and threading machine. First, the longitudinal and transverse ribs of the steel bar joints are stripped and cut to make the column diameters of the steel bars reach the same size before threading, and then rolled into straight threads. Finally, a specially designed straight thread sleeve is used for connection. The construction steps are as follows:

In such large-scale hydropower projects, vertical shafts and inclined shafts usually bear high stress, complex loads and harsh environments. The ribbed straight thread sleeve connection technology has extremely high strength, precision and durability, and thus is one of the preferred solutions for reinforcing bar connections in vertical shafts and inclined shafts.

Airports involve large facilities such as terminal buildings, runways, and aprons, with a large amount of steel bars used and complex nodes (such as large-span beams and columns, thick plate foundations), and high seismic requirements. The ribbed straight thread sleeve connection ensures the strength and ductility of the connection nodes.

In super high-rise buildings, the connection construction of vertical main bars of core tube shear walls, longitudinal bars of frame columns, and main bars of large-span beams, etc., needs to comprehensively consider structural safety and seismic performance. Straight thread sleeves effectively ensure the stability and safety of steel bar connections in super high-rise buildings.