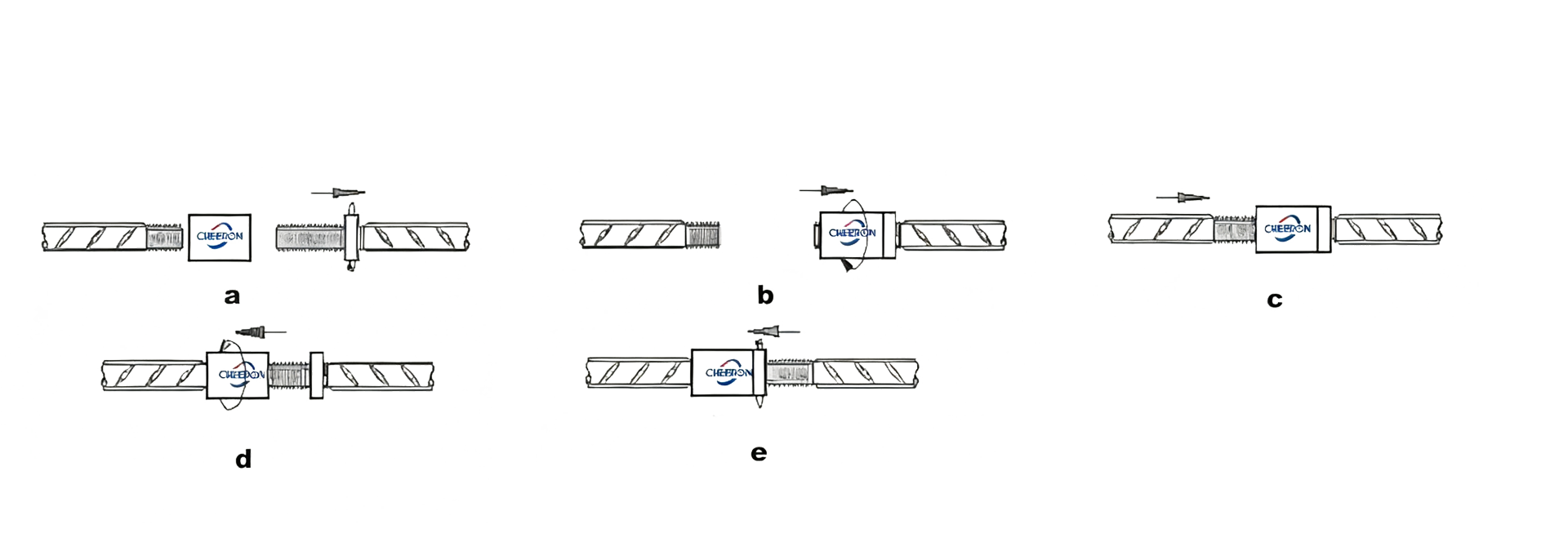

Screw the lock nut and the connecting coupler into the extended thread in advance, then screw in the thread at the end of another reinforcing bar, and lock the connecting coupler with the lock nut. It is applicable to the situation where two reinforcing bars cannot be aligned in the connecting coupler, and the thread clearance is eliminated by the locking force.

| ||||

| Rebar Diameter | Outer Diameter(mm) | Length(mm) | ||

| mm | ||||

| Rebar Strength Level ≤400 | Rebar Strength Level 500 | Rebar Strength Level ≤400 | Rebar Strength Level 500 | |

| 12 | 18 | 19 | 28 | 32 |

| 14 | 21 | 22.5 | 32 | 36 |

| 16 | 24 | 25.5 | 36 | 40 |

| 18 | 27 | 28.5 | 41 | 46 |

| 20 | 30 | 31.5 | 45 | 50 |

| 22 | 32.5 | 34.5 | 49 | 54 |

| 25 | 37 | 39.5 | 56 | 62 |

| 28 | 41.5 | 44 | 62 | 68 |

| 32 | 47.5 | 50.5 | 70 | 76 |

| 36 | 53 | 56.5 | 78 | 84 |

| 40 | 59 | 62.5 | 86 | 92 |

| 50 | 74 | 78 | 106 | 112 |

Threaded sleeve connections can be used on site to connect 12 to 50mm(#4 to #14) vertical, horizontal or any inclination Angle HRB, TMT and other high-strength reinforcing bars.

Construction method: One end of the reinforcing bar is processed into a full wire, and the other end is processed into a straight wire, which is connected through a lock nut and a sleeve. Screw the lock nut into the extended thread of the reinforcing bar, screw the connecting sleeve into the other end, then rotate the connecting sleeve in the opposite direction and tighten the lock nut.

It is used in situations where the threaded rebar cannot rotate at all, such as bending reinforcing bars and the mutual connection of reinforcing bar cages in Bridges, cast-in-place piles, etc.

Add anti-loosening lock nuts to prevent loosening caused by vibration.

As the longest lake bottom tunnel in China, the horizontal distribution bars on the side walls of the standard section are quickly connected by lock nuts

Bored cast-in-place piles are interconnected through lock nut straight thread sleeves in a mud environment