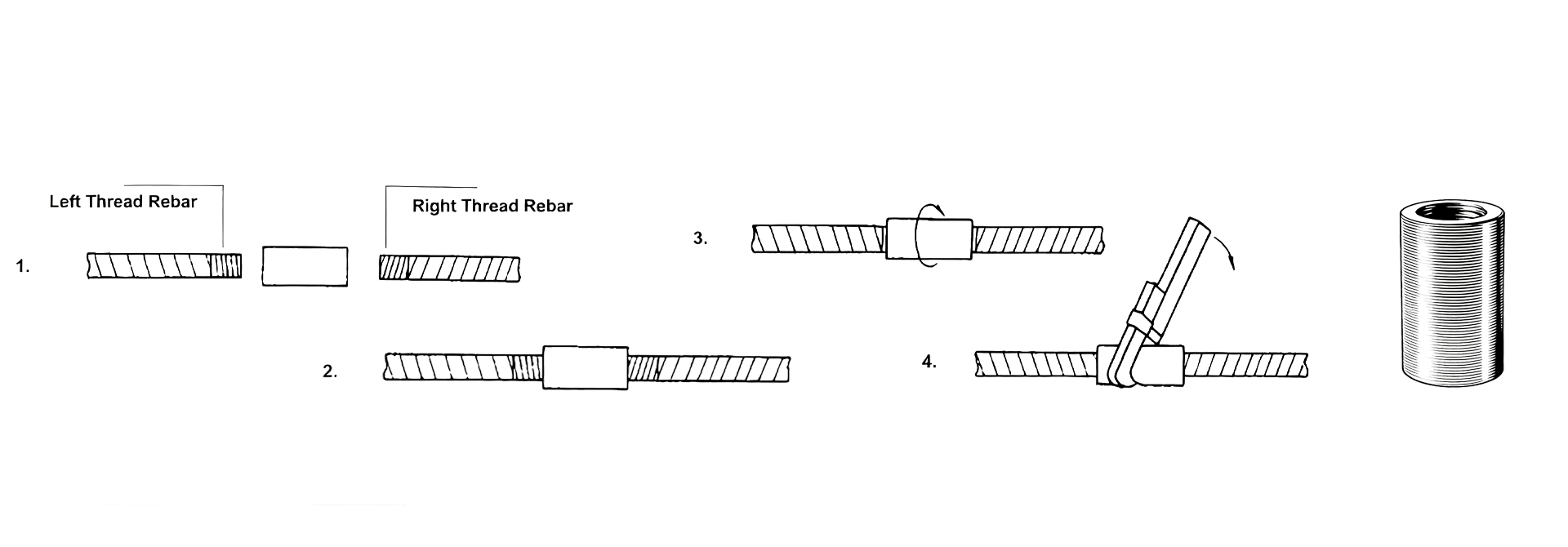

By connecting with a positive and negative thread sleeve, the two reinforcing bars can be loosened or tightened in one rotation direction, thus achieving the connection through the rotation of the sleeve without rotating the reinforcing bars. During the construction process, when the support beams, wall columns and the end of the transfer layer are completed, at this time, one of the reinforcing bars has been fixed by the concrete, and the tail of the movable reinforcing bar bends and cannot rotate 360 degrees, it is necessary to use a positive and negative thread (bidirectional) sleeve.

| Rebar Diameter mm | Outer Diameter(mm) | Length(mm) | ||

| Rebar Strength Level ≤400 | Rebar Strength Level 500 | Rebar Strength Level ≤400 | Rebar Strength Level 500 | |

| 12 | 18 | 19 | 28 | 32 |

| 14 | 21 | 22.5 | 32 | 36 |

| 16 | 24 | 25.5 | 36 | 40 |

| 18 | 27 | 28.5 | 41 | 46 |

| 20 | 30 | 31.5 | 45 | 50 |

| 22 | 32.5 | 34.5 | 49 | 54 |

| 25 | 37 | 39.5 | 56 | 62 |

| 28 | 41.5 | 44 | 62 | 68 |

| 32 | 47.5 | 50.5 | 70 | 76 |

| 36 | 53 | 56.5 | 78 | 84 |

| 40 | 59 | 62.5 | 86 | 92 |

| 50 | 74 | 78 | 106 | 112 |

The left-right thread positional coupler features can connect 12 to 50mm(#4 to #14) vertical, horizontal or any inclination Angle HRB, TMT and other high-strength reinforcing bars on site.

The tensile strength is higher, reaching that of the base material of the reinforcing bar. Bidirectional tensile tests were conducted on the connection of positive and negative threaded reinforcing bars, and fatigue performance tests were added. All results were qualified.

Construction method: Firstly, process the two ends of the reinforcing bars into positive and reverse threads respectively. Screw the sleeve into the positive thread end of the reinforcing bar with 2-3 threads. Then, align the reinforcing bars to be connected with the reverse thread sleeve end and rotate the sleeve back with 1-2 threads. At this point, both sides of the threaded rebar are screwed in with 1-2 threads. Finally, use a reinforcing bar wrench to rotate the sleeve to complete the installation.

Application: It is used for the connection of reinforcing bars where one end of the bar cannot rotate but can move axially, such as the connection between the end of a beam and the top of the beam. A reinforcing bar connection sleeve with positive and negative threads should be selected.

The main reinforcement diameter of high-speed railway bridge piers is usually Φ28mm to Φ40mm. The bidirectional screwing of the reinforcement is achieved by using positive and negative wire sleeves, avoiding the problem of rotating the reinforcement with traditional single-wire sleeves (especially suitable for the situation where the reinforcement at the fixed end cannot be rotated).

Steel bar sleeve connection is a key link in the construction of high-rise buildings, directly affecting the seismic performance and load-bearing capacity of the structure. Thousands of tons of steel bars bear huge gravitational loads. The connections need to match the mechanical properties of steel bars of different diameters to avoid the formation of weak points.

In the project, the forward and reverse thread sleeve system is commonly used to handle steel bars of different diameters and extreme environments.